Up to 20 MVA, 36 kV Class

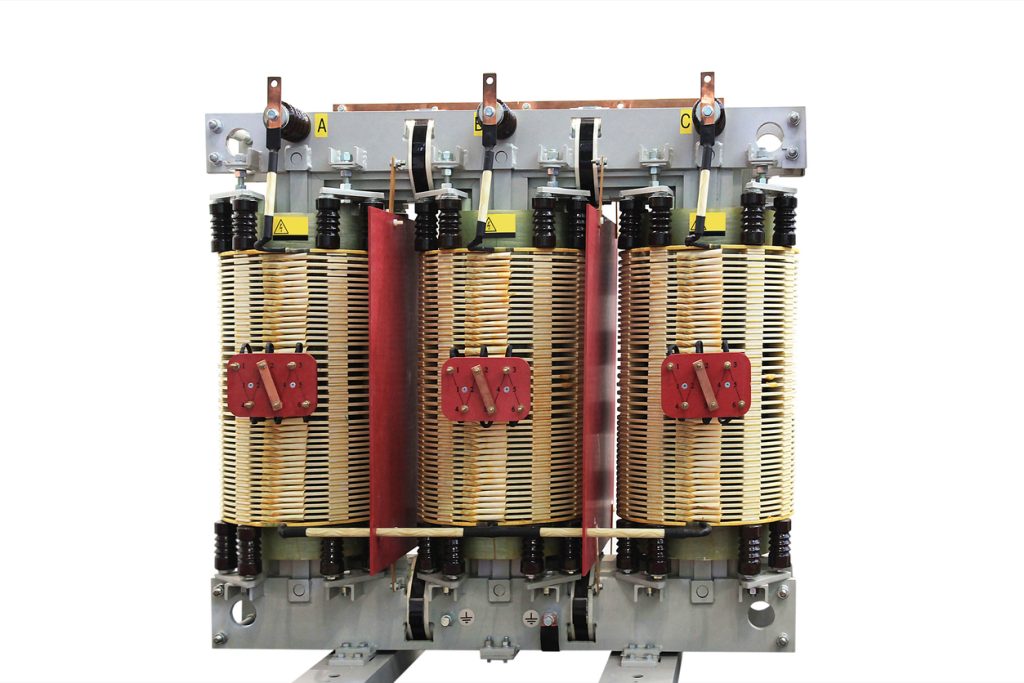

Premier Transformer designs and manufactures both Vacuum Pressure Impregnated (VPI) and Cast Resin Dry-Type Transformers, engineered to meet precise customer specifications as well as national and international standards (such as IEEE, IEC, and IS).

Our product range covers distribution and medium-power transformers up to 20 MVA, 36 kV class, available with Class F or Class H insulation systems, depending on the application requirements.

Each transformer is designed and manufactured using advanced processes that ensure exceptionally low levels of partial discharge, high electrical reliability, and long operational life — making them ideal for use in commercial, industrial, and renewable power applications.

Premier Transformer is among the few manufacturers in India qualified to perform the E2-C2-F1 testing on transformers as per IEC 60076-11:2018 standards. This certification demonstrates compliance with the highest international requirements for environmental (E2), climatic (C2), and fire resistance (F1) performance categories.

Premier Transformer utilizes a three-limb core construction made from Cold Rolled Grain Oriented (CRGO) silicon steel sheets, precisely cut as per approved drawings. Each sheet is supplied with an inorganic insulation coating to ensure superior electrical performance and reduced losses.

The circular core cross-section is achieved by assembling multiple step-laminations of varying widths. The number of steps and step dimensions are carefully optimized for maximum magnetic efficiency and minimal losses. Mitered joints are employed between limb and yoke plates to reduce joint reluctance and improve flux distribution.

The assembled core is tightly bound with fiberglass tape banding, which minimizes vibration and reduces noise levels. A protective surface treatment is then applied to safeguard the core from atmospheric corrosion and extend service life.

Both High Voltage (HV) and Low Voltage (LV) windings are made using high-conductivity copper conductors. Depending on current and design requirements, round wire, rectangular strip, or foil conductors are used. The winding configuration—layer type or cross-over type—is selected based on the transformer’s current and voltage ratings.

All windings are vacuum cast using an advanced automatic casting plant supplied by Heidrich, Germany, ensuring void-free insulation and high dielectric strength.

On the HV side, inserts are provided for tap-changing links. Interconnections between HV phases are made using formed copper tube links, with terminals shaped into lugs for secure connections. These links are further insulated using heat-shrinkable sleeves for enhanced electrical safety and reliability.